Browse Categories

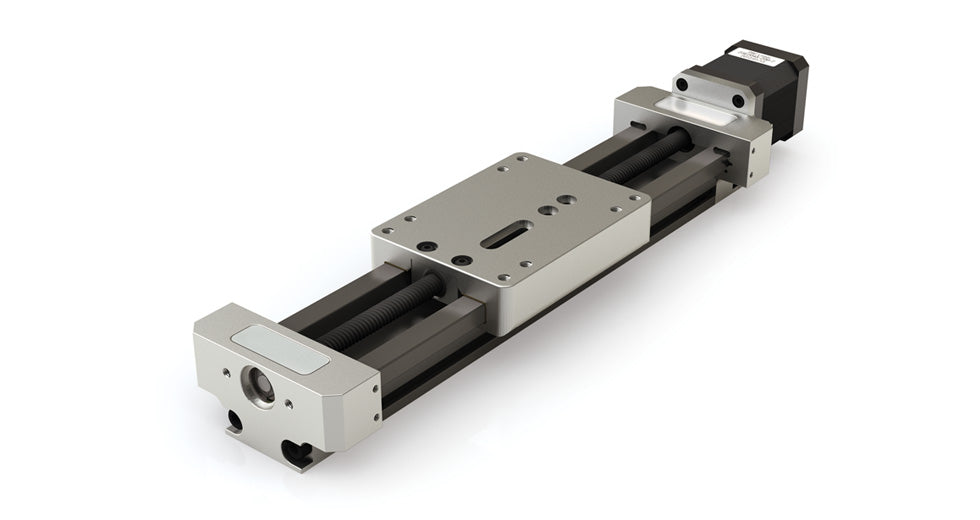

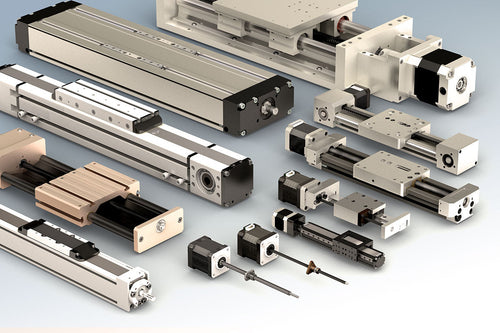

Linear actuators produce controlled straight-line motion by combining a linear guide system with a drive mechanism and power source, making them a core building block in modern automation. Across the industry, they are commonly classified as pneumatic, hydraulic, electric, or purely mechanical, with electric and mechanical designs increasingly favored for their precision, cleanliness, and ease of integration. PBC Linear focuses on electric and mechanical linear actuators built around lead screws, ball screws, and belt drives, including motor-driven configurations. Belt-driven actuators are well suited for long strokes and high speeds with minimal maintenance, ball screw-driven designs deliver high accuracy and load capacity for demanding positioning tasks, and lead screw-driven actuators offer a cost-effective, quiet solution with options such as anti-backlash nuts for improved repeatability. These systems are available in a wide range of screw diameters, lead sizes, and lengths, and can be configured for manual operation using hand brakes or cranks, or for automated operation with NEMA motor-driven electric systems. Carriage guidance is supported by either self-lubricating Gliding Surface Technology for smooth, low-maintenance motion or ball bearing profile rails designed to handle higher moments and cantilevered loads. Together, these options span miniature to heavy-duty applications, supporting loads up to 83,400 N (18,750 lb) and strokes up to 6,000 mm (236 in).

Product Features of Linear Actuators

Recently Viewed Products

- Choosing a selection results in a full page refresh.

- Opens in a new window.