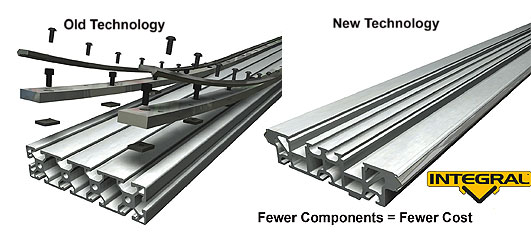

PBC Linear's Integral V™ Technology (IVT) has the ability to simplify linear guide systems without painstaking labor and alignment. IVT linear guides were designed as the next generation in V-guide technology. Hardened steel inserts embedded directly into aluminum structural framing provide fast, accurate and long-lasting travel without additional fastening components, alignment or labor. Typical V-guide products require mounting fasteners, plates and bolts to adhere V-races onto structural framing; resulting in increased tolerance stack-up, or steadily accumulated variation in the products performance.

Stacked against the competition, IVT shines as the obvious choice for cost efficiency. It simplifies all aspects of integrating a new linear guide system, design, installation labor, material costs, and performance. For a definite picture of how IVT saves on cost, we IVT compare the product to its closest competing product: V-guides.

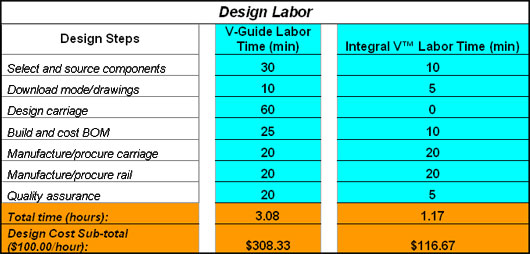

Linear motion engineers work tirelessly when designing a new system. This process can take hours, days and, in some cases, weeks to plan out appropriately—causing labor costs to skyrocket. Within a linear guide system integration process, design engineers have the highest labor cost; therefore a streamlined product that saves hours in design time could potentially save a company thousands of dollars.

Example application: Company X needs a linear guide system for a 1 meter application under general load, speed and environmental capacities.

Using the given example, design time for this general application is broken down in the Figure below:

Conclusion: Due to eliminated tolerance stack-up, PBC Linear’s availability of design models, and IVT’s simplified design, the customer is able to save a potential 63% on projected labor costs before the product is even ordered.

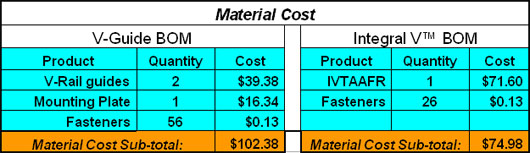

A V-guide system carries more additional components than two V-rails. It has an entire inventory of fastening and mounting materials. This not only presents tolerance and alignment issues, but also steadily increases the Bill of Materials (BOM).

Conclusion: Over a length of 1 meter, IVT linear guides are able to save the customer 27% on material costs. This is due to the hardened steel embedded raceways; which are permanently adhered to the aluminum extrusion without the need for fasteners. IVT’s innovative design and proprietary machining process allow for enhanced performance without enhanced component inventory. Using half of the fasteners required for V-guide technology, IVT provides precision linear guidance, smooth travel and sophisticated operation.

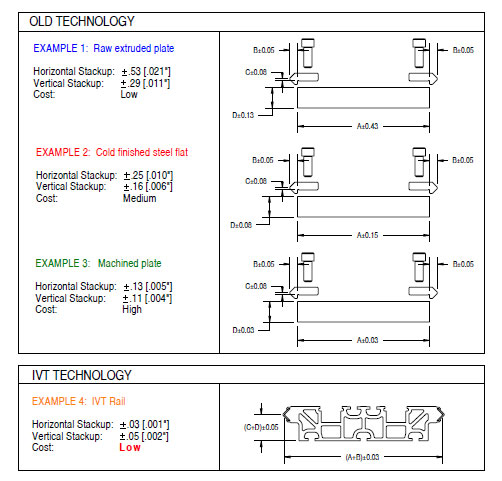

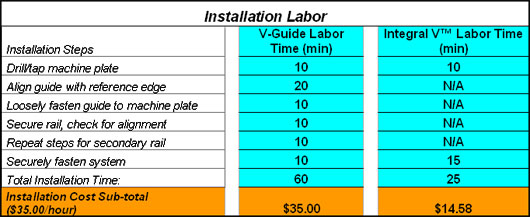

The design is specified and the materials are ordered. The final step is to install the system. With V-guides, the installation process is complex, requiring constant checking and re-checking alignment of the V-guide rails to the machining plate and the machining plate to the aluminum extrusion. IVT’s simplified design eliminates tolerance stack-up; which also reduces alignment issues.

As shown above, V-guides’ additional components cause steadily increasing variance and inaccuracies for the linear guide application. However, installation requires more than alignment.

Conclusion: As shown in the Figure above, IVT saves the customer on time, cost and labor. This next-gen linear guide product is easy to specify, saves on materials, and installs in a fraction of the time versus the older technology. How is it able to accomplish this? IVT’s competitive edge begins with PBC Linear’s proprietary SIMO™ process (Simultaneous Integral Milling Operation). SIMO ensures accurate travel and precision by concurrently machining all qualified edges at once. This process rectifies the natural bow twist and camber variance in aluminum extrusions. V-guides, relying on outdated and expensive machining techniques, dramatically increase a customer’s labor and production costs.

In the example application, IVT delivers a 47% overall cost savings over the traditional V-guide product. But does this make it more reliable? The proof is the performance. IVT saves on cost NOT because it’s a substandard product, but because it re-imagines the design of the traditional linear guide. IVT is designed to hold tight tolerances (±0.001"/0.025mm), precise parallelism (±0.001"), and machined straightness (±0.002"/ft). This allows IVT to deliver sophisticated, reliable and smooth linear guidance for several applications and industries. Available in multiple different profile structures along with custom options, IVT is shown to be more versatile than competing technologies.