For precise linear travel within a small footprint, look to the ML series of miniature linear actuators. Customers can fine an instant fit within small-scale automation markets such as laboratory, medical and packaging applications. These actuators are:

The ML series is made up of three styles that include MBL, MLC, and MLD. All three are designed for performance and customer satisfaction in single and multi-axis assemblies. Evidence of this high performance is apparent with the Golden Mousetrap Best Product Award in Motion Control. This award from Design News celebrates the year’s top products in innovation, creativity and product design.

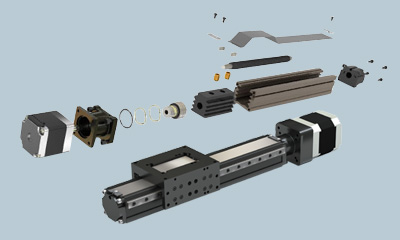

The ML series puts the control in the customers’ hands by letting them choose the configuration that best suits their application. The MLB comes complete with a state-of-the-art motor for powered, automated control. The MLC features a motor mount for easy coupling to a motor of the customers’ choice. Finally, the MLD has a hand-turned knob and break for precise, manual control applications.

These actuators offer our customers a versatile range of motor mounting options. Utilizing universal motor mounts, these mini-actuators give customers the flexibility to fit into small spaces. Straight or in-line mounting with a coupler is one basic option. In addition, a “J-drive” type option is available with the motor being located above, below, or to the left or right of the slide.

The ML mini-actuator’s unique compact motor mounting adaptor allows the pairing of standard stepper and servo drive motors while minimizing overall length. Mounting the actuator is done simply by using clamps on the integral dove tail shaped slots located along each side close to the base. Limit switches and other accessories are simply mounted to the T-slots that are accurately positioned along each actuator’s side. The carriage has two threaded inserts to ensure dependable and convenient mounting to the carriage.

In addition, several different sizes of drive screws give customers a wide selection of velocities to choose from. With the possibility of having up to two profile rails, moment capacity for the ML is dramatically increased. Also, to allow for function in contaminated and clean-room environments, a seal strip can be added to keep dirt and grime out of the system while keeping all particulates from exiting the system.

Mounting configurations can be used with any of the motor options available. These include NEMA 11, 14, 17, and 23 stepper motors with either a single, double, or triple stack as well as state of the art servo motor options.

The ML series features several design features that promote high performance, precise travel, and power. The outer body profile is precision machined using our patented SIMO® process. This process uses multiple synchronized cutters that produce an actuator with concurrent and consistent machining on all critical edges, ensuring extremely tight tolerances, high accuracy mounting, and low costs. It also reduces weight, allowing for a smaller motor to drive the actuator. The ML series “dovetail” style carriage comprises 14 plain bearing surfaces that support low-friction, smooth motion, and quiet travel. Optional single or dual external linear guide supports can be added for enhanced stability and load capacities.

Internally, the ML series mini-actuators are built for performance. With a larger diameter lead screw, these miniature actuators can support higher load capacities at greater accuracy. Duplexed and lead screw support bearings provide high stiffness, increased thrust load, and repeatability. An optional anti-backlash nut is also available on the ML series for applications that require high bi-directional accuracy. The final assembled product offers users both precision and performance, while delivering long-lasting linear guidance in tight, diminutive spaces.

The lightweight ML series, with its precision-machined outer profile, can be easily fit on to any axis. Motor mounting is also a snap, as they can be mounted in-line, on the side, or top or bottom of the actuator as space permits. This is a crucial benefit when implementing a multi-axis design. Furthermore, PBC Linear has compiled a full assortment of accessories, design options, and replacement kits, along with full ML specifications within our new ML series catalog. ML miniature actuators in the medical industry

Our miniature linear actuators have been showcased within the medical laboratory environment, but recently a medical supply company decided to incorporate the small actuator into a cabinet locking system. Using their smallest model, our application engineers were able to collaborate with this medical company to design an automated keypad lock for a transportable medical storage unit.

Security is of the utmost importance when housing delicate and expensive medical supplies. To maintain control over their stock of medicine, tools and other delicate devices used, the medical supply company required a linear positioning system small enough to fit into their compact drawers and install into a keypad lock system. The lock required precise, smooth, and quiet linear motion to successfully operate the locking pin in and out of position. Traditionally in these systems, a solenoid is used to operate the locking mechanism. However, the clinic found solenoids to be too inaccurate for reliable and repeatable performance on necessary tasks. The ML is also equipped with a special, no maintenance self-lubricated polymer slider to support the actuator’s compact design and facilitate stable linear guidance.

After installation, the medical clinic reported satisfaction with their locking systems. The compact linear actuator easily fit into the small space, supplying efficient and dependable motion to lock and unlock the portable medical cabinets whenever they were needed.

For more detailed information on our line of actuators, download the Mechatronics Enabled Systems catalog.