A common misconception in reviewing accuracy and repeatability in linear motion systems is that they refer to the same thing, however they do not.

The following are the accurate descriptions of each:

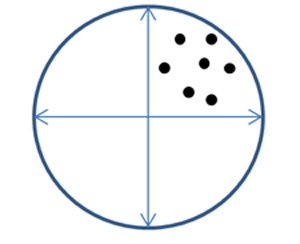

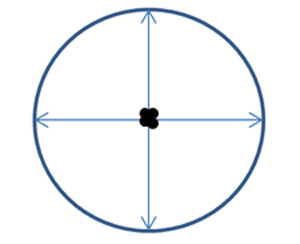

Accuracy

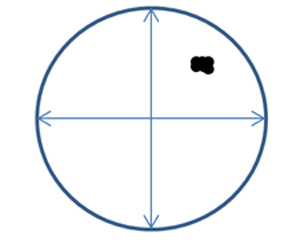

Repeatability

Errors in accuracy and/or repeatability may be derived from the “six degrees of freedom,” which are as follows:

Knowing whether one, or all, of these six degrees of freedom are required involves a thorough understanding of the application at hand. Within these six degrees of freedom, there are many different elements that can cause variances in accuracy. Some of the elements that may contribute to error in a basic actuator include, but are not limited to:

When looking at things such as the base unit of an actuator, the key variances to keep in mind are thickness or height (Z-axis), twist (X-axis), and bow/arch (Y-axis). What cannot be forgotten is that elements of other components can cause inaccuracies, so it is imperative that each be evaluated individually. Something such as a lead screw in combination with a nut, which can provide backlash tolerance, is a great example of other contributing factors to consider. Other elements to evaluate include, but are not limited to:

If you require assistance in building a linear motion system specific to your application needs, please contact a PBC Linear application engineer.