While many linear applications are relatively short to moderate in length (12 feet or shorter), there are applications that require travel lengths in the 40 to 50-foot range, and sometimes longer. PBC Linear offers a variety of products that fulfill these various long-length requirements, including several options that can join rails end to end. Where longer travel requires butting rails end to end, we recommend a rolling element (wheel, ball, etc.).

PBC Linear often gets inquiries from customers interested in the plain bearing feature of our Gliding Surface Technology in order to solve their long travel applications. Some specific products within this family includes Uni-Guide, Low Profile Uni-Guide, and Mini Rail. In addition, our ceramic coated shafting, also known as aluminum feather shafting, and ceramic coated rail, or feather rail, both fall under the gliding surface category.

Corrosion resistance and light weights are attractive features for these product lines. Although all of them are excellent products and great choices for a wide range of applications, they do not lend themselves well for end joining. The simple reason is that linear plain bearings and carriages that employ plain bearing technology have a precise running clearance for which alignment is critical, and these end joints have a high probability for binding due to misalignment. Also, the carriages for Uni-Guide, Low Profile Uni-Guide, and Mini-Rail are matched to the rail, making the addition of rails problematic.

As previously mentioned, the product families that contain wheels, rollers, or balls are the best candidates to transition a joint along a rail/raceway. We will explore some of those product families that are suited for long-lengths, starting with Roller Pillow Blocks and following with Redi-Rail, Hevi-Rail, and IVT linear guides.

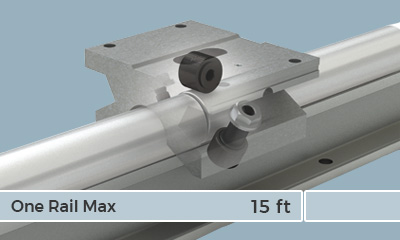

Roller Pillow Blocks use round shafting as the raceway. Large cam followers in the roller pillow block deliver industrial strength performance over long travel lengths while excelling in dirty environments. For very long runs, we recommend the hardened steel or hardened stainless steel shaft be supported by the aluminum support rail. The shaft and support rail assembly (SRA) can be butt joined for long runs, and the low-friction rollers easily navigate joined or misaligned shafts, accounting for any shaft deflection.

An example of roller pillow block implementation can be found in a cryogenic storage and retrieval application.

In this scenario, a customer needed a 3,200 lb cartesian robot on a welded steel frame to travel lengths between 22 feet and 32 feet. There were technical challenges for this aplications, including those butt joints, the addition of doweled joints along the shafts, and a welded structure that was neither straight nor square. Our roller pillow block solution included the shimming of fully supported rail for smoother travel, gaps to allow pass-throughs, opened mounting holes, and a compliant mount design.

To find out if Roller Pillow Block fits your solution, learn more by downloading our Roller Pillow Block catalog.

Redi Rail is a very versatile product and can be mounted to utilize either the radial load capacity or the axial load capacity. Referencing the coordinate axis below, a load applied in the Y direction makes use of the radial load capacity. A load in the Z direction applies force in the axial loading condition. The Redi-Rail metric series is available in 3-, 4-, and 5-wheel carriage options, and offers a preload feature.

To find out if Redi-Rail fits your solution, learn more with our Redi-Rail Linear Guide Overview video and blog.

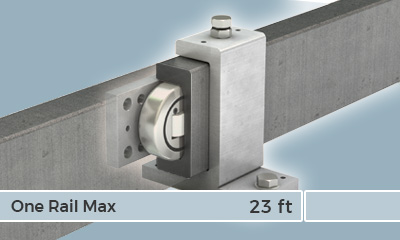

Hevi Rail is typically used in applications that require moderate accuracy. Since the rails are mild structural steel, they are easily weldable, making it possible to grind the joint smooth for ease of transition from one rail to another. The heavy load capacity makes this a good choice for those heavy-duty applications that also require long travel.

In this long-length example, we spotlight Hevi-Rail and its implementation into an automated storage and retrieval facility. Our customer needed a heavy duty bearing system with multiple heights within a vertical application. The bearing systems would need to travel as high as 14 levels, requiring lengths from 18 feet to 96 feet. Hev-Rail (HVR-4 and HVBEA-461/HVP4) were used in high volume for an initial total of 6,500 feet.

To find out if Hevi-Rail fits your solution, learn more with our Hevi-Rail: The Heavy Duty Roller Bearing video and blog.

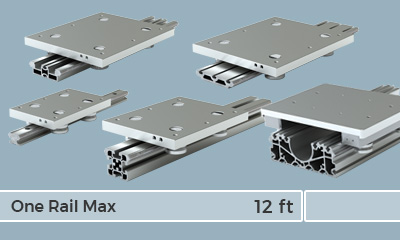

Integral-V Technology offers a range of rail profiles and corresponding carriage sizes. The maximum length of most profiles is about 12 feet, making it sufficient for most applications, but is easily butted end to end for longer runs. The V-profile wheel easily transitions the joint between rails. Most profiles allow use of a single rail due to high moment load capacity. The adjustable preload feature, combined with a maximum speed of 10 m/s makes the IVT a unique choice for a range of applications.

A long-length example of an IVT application was for an automotive production plant. The customer had already constructed belt drives to horizontally transfer parts from one machining center to another. The runs were 32 feet in length at the minimum, and 60 feet at the maximum. Our IVTABK linear guide rail was implemented as a top mounted carriage along the horizontal rail and raceways, allowing for high accuracy and quick alignment.

To find out if Integral-V Technology fits your solution, learn more with our Integral-V Technology Overview blog and video, or download the Integral-V Technology catalog.