Within the factory of the future program at Applied Cobotics, we have readily embraced the cobot nation. Initially, as we were implementing this new technology, we found that one tray of parts did not take advantage of the cobot’s full potential. We quickly realized that we needed some type of lift automation, combined with a storage and retrieval component, that would assist the cobot for much longer unattended production runs.

The ASRS assists most cobots and other robotic applications by providing a continuous arsenal of machinable parts over a much longer time frame. It does this by consistently loading and unloading dunnage trays onto the robot accessible work area, eliminating the need to manually replace each one. The resulting boost in cobot production is 10- to 20-times that of standard means.

The ASRS from Applied Cobotics features a vertical lead screw-driven shelf, and a horizontal tray loader/unloader. In addition, tray rack towers engineered for the ASRS offer open-spaced shelving that accommodate various part sizes up to 18-inches in height. The rack towers are also capable of holding up to 17 trays. Customized dunnage parts trays can be acquired either through our 3D printing and thermoforming capabilities. For DIY customers, purchase one of our 3D Platform or BCN3D printers and create your own custom trays!

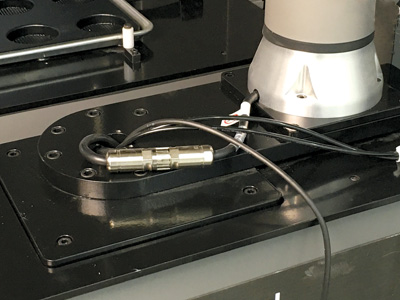

The ASRS works by assisting a robot in longer parts runs. Without the ASRS, a robot will stop running as soon as it finishes that one tray of parts. With the ASRS in place, the robot system is capable of unmanned, continuous production. As the cobot finishes each set of parts on the tray, the tray loader slides the finished parts tray to its predetermined position, and then pulls the next one onto the shelf. Once the tray is pulled into position, the cobot is alerted and automatically resumes its project tasks. Depending on the parts, a project can operate unaided overnight, making each one a potential lights-out automation run. Built-in motor encoders provide highly accurate motion, maintaining the tight tolerances that cobots require.

All together, these features provide reliable and safe load-handling for any part type or size. The ASRS can easily be implemented to automate most CNC lathes, Mills, and many other types of robotic-aided manufacturing for long-running, unattended operation.

ASRS is offered as a package deal with an attached cobot, or as a single component.

Tray loader provides smooth and reliable loading of parts trays.

Vertical shelf feature moves in sync with the multi-tray rack.

Mounting feature provides an option for attaching robots.

Tray rack feature offers longer part runs for robots.

As customers begin to request more custom components, shorter part runs, and cheaper costs, there is an increasing demand for flexibility on the shop floor. The Automated Storage and Retrieval System from Applied Cobotics, in tandem with many types of robots, provides project managers and operators that flexibility. While Applied Cobotics offers the ASRS and cobot as a package deal, the ASRS can be purchased on its own, providing an essential asset to existing automation systems. It offers its own adaptive features such as:

The ASRS from Applied Cobotics is easy to use, and does not require any extensive programming knowledge. For CNC milling machines, our experience has proven that the time investment is less than one day to fully implement the ASRS/cobot package. Other ease-of-use features include:

In addition, the safety characteristics of cobots has been applied to the automated material lift system. If a human worker or any object gets too close the ASRS, a floor sensor will alert the ASRS to pause its motion until the area is clear again. Use any of the links below to find out how Applied Cobotics is making automation easy for SMEs!