When using automated systems to measure samples, accurate positioning and precise travel is key. Recently, PBC Linear was approached to design a fully automated CNC drilling system for laboratory test tube analyzing and storage. In order to ensure precision positioning and drilling, PBC Linear recommended their ML series miniature actuators.

The application required a CNC drilling system that would drill holes on a 12 inch x 12 inch area, creating a peg board. These holes would, in turn, be filled with medical test tubes for safe storage while they await being analyzed in laboratory centers across the country. The medical equipment manufacturer needed a quick, precise and durable mini-positioning system; therefore, PBC Linear designed a complete turnkey solution using three MLB motor driven actuators assembled in a sophisticated XX’Y configuration.

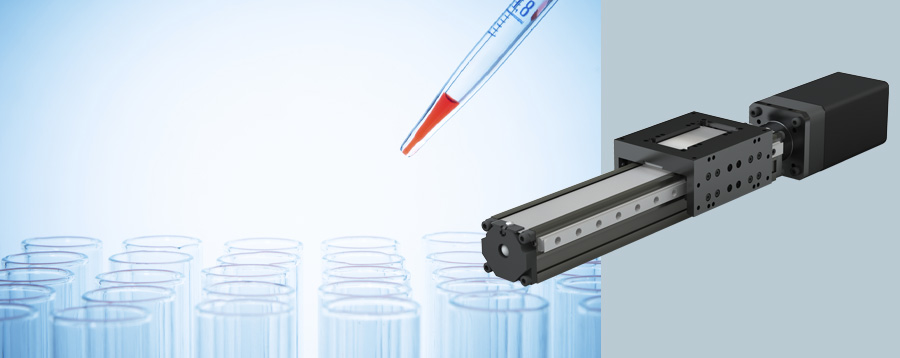

Designed for precision in a small-scale environment, the MLB actuator ensures accurate positioning performance. The mini-actuator comprises a post-processed SIMO™ machined outer profile for precise mounting and durability. This one-of-a-kind machining process allows for fast, simultaneous machining on all critical edges of the body. It also permits the actuator to sustain a lighter weight without sacrificing strength—allowing for a smaller sized (and more affordable) motor. The MLB mini-actuator’s “dovetail” style carriage comprises 14 plane bearing surfaces that provide low friction, smooth motion and quiet travel. Power is supplied by a state-of-the-art stepper motor system for optimum control. The final assembled system is at the pinnacle of both precision and performance.

Moving at a speed of 10 inches/second, the CNC drilling system was able to provide advanced positioning and drilling across the pegboard’s surface area.