To create a solar panel, silicon ore needs to be fused in a furnace similar to how glass is made from sand. These furnaces are immense, and require a multitude of precision components to work in harmony for the succesful creation of silicon ingots. The ingots are then sliced into thin sheets for the fabrication of the solar panels. A heat damper provides precise temperature control during the process. If this delicate process is upset, production time and cost would exponentially increase as these furnaces are heated to thousands of degrees and take days to cool down for servicing. To control the critical lifting and positioning of the damper, the manufacturer required a linear system that was low cost, precise and reliable in order to compete on an international level.

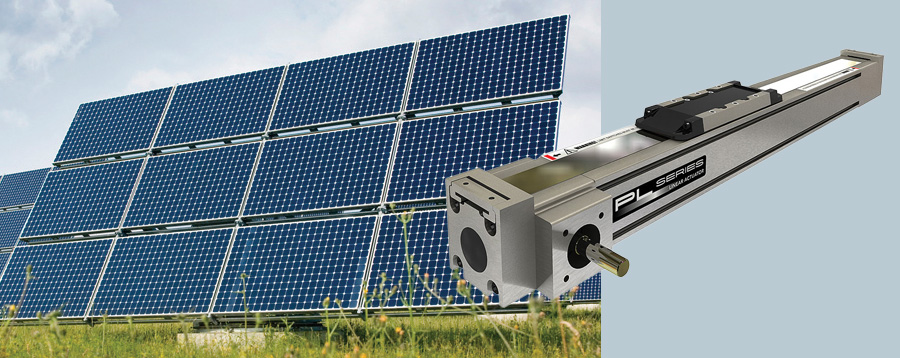

PBC Linear’s PLA ball-screw driven linear actuator was the answer. The PLA stands out from its competition with its SIMO™ (Simultaneous Integral Milling Operation) machined profile that mills out tight, consistent tolerances on all sides of the system to ensure repeatable guidance at no added cost. The PLA is also equipped with Integral V™ Technology (IVT) to provide enhanced precision guidance of the actuator’s V-rollers. When these advantages combine together, they create a superior linear actuator with no additional costs to the end user.

The silicon ingot manufacturer was immediately impressed with the PLA’s performance and reliability. Since implementation, the actuator has been running successfully, aiding in the production of solar panels and helping jumpstart the renewable energy industry.