SigmaPro Engineering and Manufacturing is custom manufacturing and micro injection molding company that's based in Texas, and has been in operation for over 20 years. They pride themselves on matching innovative solutions to customer ideas, and then bringing them to fruition in an expedited time frame. This translates into products that are better designed up front, and therefore less costly to produce overall.

Injection molding is a large volume manufacturing process, typically producing thousands or even millions of parts in succession. The process utilizes high-pressure, heated plastics forced into molds to create a wide variety of products such as household containers, automotive components, and healthcare tools. Injection molding uses two types of plastic materials: thermoset which cures once exposed to air; and thermoplastics which can be melted and recycled for reuse.

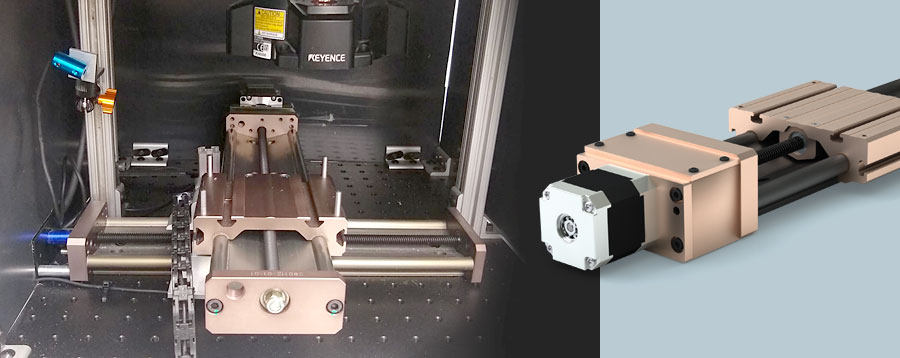

At SigmaPro, customers have come to rely on their innovative spirit and attention to quality to deliver consistent results. In this application, SigmaPro needed a linear guide system that would accommodate their new inspection equipment. The application includes an XY stage that moves in accordance with a camera system, inspecting product as it comes out of production. The inspection system cycles between multiple parts ranging in size from 5 to 8 mm, detecting any potential defects that are typically no bigger than 1 mm2. Precision motion is therefore essential for processing accurate and repeatable measurements.

This demand for high precision meant the linear guide system would also need to be highly accurate. Other parameters included NEMA 17 or NEMA 23 mounts, and XY guides with the desired stroke and mounting options.

The original components included a ball screw-driven linear carriage with rubber wheel rollers moving along an aluminum 8020 frame. The rubber rollers allowed for too much hysteresis and wiggle room, making the linear system inefficient, imprecise, and in need of frequent maintenance. These combined issues necessitated an immediate upgrade for the inspection process to function correctly.

SigmaPro worked with our Application Engineer to identify which series of stages would provide the best solution. For the new XY upgrade, they chose the dual design of the Uni-Guide Actuator from PBC Linear to help streamline their application. Each linear actuator kit is over thirteen inches in length, and comes equipped with a Teflon-coated lead screw drive and our own self-lubricating, Constant Force anti-backlash nut. These features, along with a lead screw accuracy of 0.003 inch/foot, provide a high degree of bi-directional positional repeatability.

Uni-Guide comes with the option of a NEMA 17, 23, or 34 motor mount kit. The engineers found that the actuators “worked amazing with NEMA 17, but did have to upgrade to NEMA 23 in order to get more speed out of the system.” They also found that the stepper motor, in conjunction with the lead screw drive, moves the stage in a very accurate pattern, with no hysteresis or skipping.

The Uni-Guide plain bearing assembly is constructed of a single, standard carriage that uses our Simplicity® bearing with FrelonGOLD® liner to glide along parallel shafts. The two-piece construction and gliding technology proved to be the perfect upgrade from the less reliable moving parts of the original iteration. The dual shafts, or guidance profiles, are machined into one rail, providing built-in alignment that ensures repeatability and reliable outcomes.