The 150,000 square-foot manufacturing hub at PBC Linear provides a wide selection of sophisticated linear motion technologies to a growing global customer network. Our product catalog ranges from linear bearings to full actuating systems. We blend the newest software, the sharpest engineers, and the latest tools and technologies to form a fully integrated manufacturing system.

In our push for progress, PBC Linear has completed the construction of its new manufacturing facility. This state-of-the-art building, adjacent to the existing facility, includes over 66 thousand square feet of space and contains an optimized manufacturing floor with supporting offices. In addition to the new building, we have made significant advancements in machinery and equipment at both the current and new facilities. Together, these investments are aiding in further streamlining the company’s operations, increasing efficiency and productivity, and continuing to meet growing industry demands.

Innovation has been a hallmark of PBC Linear since its inception as Pacific Bearing Company in 1983. With more than 15 pending patents, we continues to develop products that reduce components, improve performance, and streamline assembly, giving customers a competitive advantage. From our trade-secret method of sizing Uni-Guide™ and Mini-Rail, to the patented SIMO process, PBC Linear continues to be a leader in linear motion technology. Innovative products and advancements include:

Some motion control companies structure their production on foreign, low-cost labor. PBC Linear has created a manufacturing floor utilizing sophisticated production equipment, resulting in a high level of efficiency and automation. Through these and other innovative processes, we can support a 24/7 production schedule. Customer benefits and services include:

Our engineering team is comprised of multi-disciplined engineers, drafters, and model makers. They utilize a range of advanced manufacturing techniques designed to meet customer requirements. this flexibility allows them to either design a logical extension of an existing core product, or create a customized, innovative solution for a complex linear motion application. As a whole, the team strives to produce superior products, and when that production technology is not available, they invent it. PBC Linear incorporates the latest in technology tools, including:

PBC Linear turns, mills, and grinds virtually all products in-house, ensuring maximum quality without affecting lead times. These complex manufacturing tools require experienced technicians to run them. We support this group of machinists and tradesmen (and women) by supplying them training in the latest techniques and equipment. Customer benefits and services include:

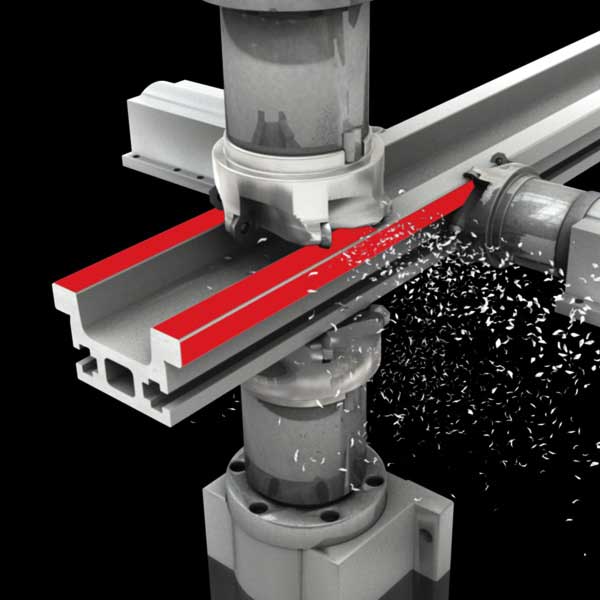

Our recently-designed SIMO machine (Simultaneous Integral Milling Operation) brings a high degree of precision to the aluminum extrusion process. The SIMO process uses synchronized cutters that machine all critical edges concurrently in one pass, eliminating built-in extrusion variances. The result for customers is an extremely accurate product, produced in minutes instead of hours, and with minimal extra costs. More specific benefits include:

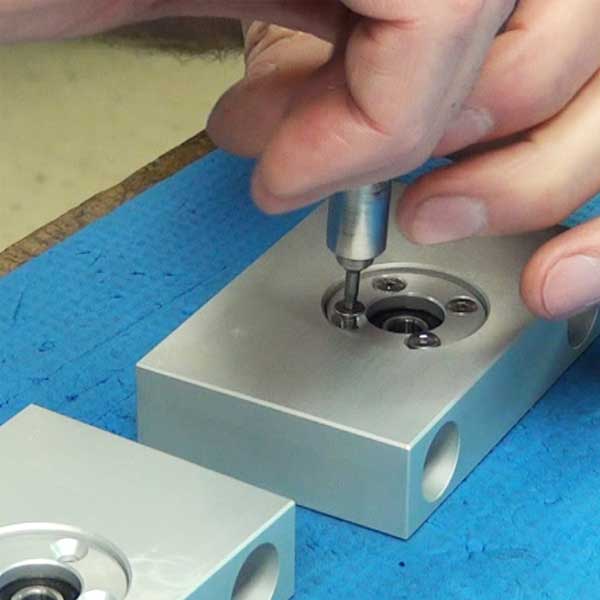

Our high-end assembly room is used to design and build custom, high-end application products for a wide variety of industries. We produce best-in-class, motion-control systems using methods that include:

When it comes to implementing new ideas, PBC Linear draws from decades of combined experience and matches it with the latest machining capabilities. Our specialty toolmakers and fixture machinists are the best at creating new solutions for client's motion control applications. Their high level of expertise within all facets of production yields quick turnarounds on new working prototypes, as well as improvements to existing designs. In summary, the PBC Linear specialty design team is:

Each PBC Linear product is hand-inspected by trained professionals, and machines are routinely checked to ensure optimal function and outcomes. Further quality control and testing procedures include: