In this video, one of our expert product managers introduces the roller bearing pillow block system from PBC Linear as a problem-solving linear motion product. Within this video and outline below are some of the advantages of our roller pillow blocks.

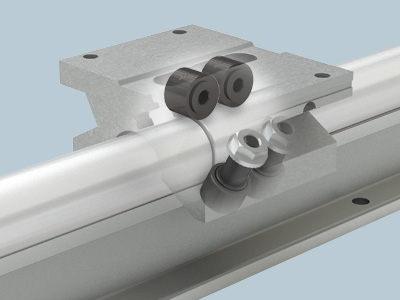

Design Compatibility: We first compare the PBC Linear roller pillow block to a traditional recirculating ball bearing block. We notice that they have similar mounting holes and center-line, giving roller pillow block complete size interchangeability with industry standard blocks. This offers the advantage of performance benefits without the need to redesign the existing linear motion system.

High load-capacity roller bearings: Their large diameter provides a range of advantages for shaft diameters from .5 inch to three inches:

High Performance: Roller pillow blocks offer dynamic load ratings that range from 800 to 12,500 pounds, and a low coefficient of friction that helps to achieve speeds up to 25 feet/second.

Installation: Roller bearing pillow block design achieves a time and cost savings during installation. The roller bearing pillow block shaft is naturally aligned vertically when using a support rail. Also, our floating option can absorb up to 0.125 inches of misalignment, reducing time and cast of installing the system. In contrast, when using traditional recirculating ball bearing designs, there is extra time and attention that needs to be given to qualifying surfaces and the alignment of the rails. This process can be expensive and impractical, and include:

Applications: Roller bearing pillow blocks are ideally suited for a wide range of applications, including:

Roller pillow blocks are available in single, double, or twin versions and come with optional features such as scrapers for severe contamination and lubrication ports for directing grease to the raceways.