OEM’s are always seeking a range of specific linear technologies in their miniature motion control applications. To address this market, PBC Linear has a large miniature rail portfolio that includes ball-type products along with the proven Frelon® self-lubricating plain bearing linear guides and driven stages. The complete line of miniature linear motion technology includes:

This miniature portfolio is available as a result of cooperation with Chieftek Precision Co, LTD (CPC), a global leader in small profile ball-guided technology. This arrangement helps facilitate collaborative product designs; such as precise, lead-screw driven linear actuators from both tribological bearing technologies to fit into the compact space of the miniature industry. The strategic basis of the cooperation is built on multiple elements; including:

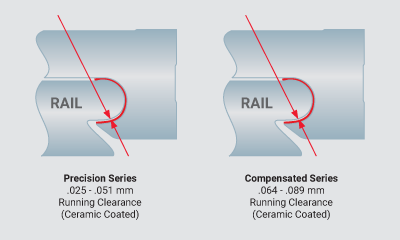

Within the family of Simplicity linear bearings, precision and compensated are terms that refer to the two classes of available running clearances. It is important to understand the difference in these two classes to ensure that bearing systems will perform properly during the design and installation process. In this article, we briefly explore these differences within our patented Simplicity® bearings and Mini-Rail linear guideways.

Mini-Rail® miniature linear guides are available with two classes of running clearance in all sizes. The 7, 9, 12, 15, and 20 mm rails are all available in either a precision version for tighter tolerances, or compensated version to accommodate greater misalignment.

Precision bearings:

Compensated bearings: