If you are a regular browser of our website, you have probably seen some references to the SIMO® process. We can quickly summarize this as a proprietary process that ensures precision machined extrusions with incredibly tight tolerances that are consistent throughout the length of the rail. Sounds great, right? But what does all that mean to the design engineer?

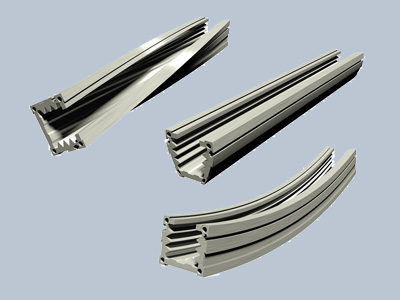

The swaging process and the method developed for manufacturing embedded raceways ensures the pre-engineered alignment of parallel rails while guaranteeing the security of the hardened steel raceways throughout the life of the unit. This process combines aluminum and steel to create a lightweight, precise, and durable solution for longer rails. All of the critical edges of the rails are then cut using the SIMO process, making them more rigid, accurate, and repeatable. This pre-engineered alignment lowers the cost of components, which in turn lowers the cost of assembly time and overall installation cost. Combined, these processes allow PBC Linear to offer more efficient and cost-effective products and services.

You can learn more about our SIMO Series linear motion platform by using these helpful reference materials: