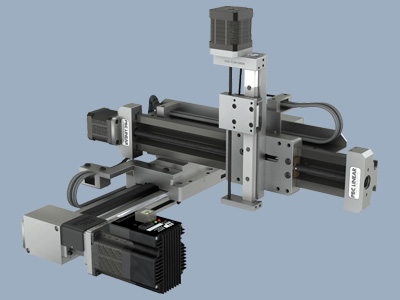

The Mechatronics Enabled (ME) initiative from PBC Linear provides a range of mechatronics solutions for small, medium, large and extra-large applications. For 3D Platform, a manufacturer of large-format 3D printers, the world-class motion control for their XYZ gantry is designed with linear actuators from the mechatronics enabled, industrial strength UG Series with SIMO process®.

UG Series actuators from PBC Linear have been a core component for the 3DP printer from the beginning because of their high rigidity, accuracy, and reliability. Our actuators are equipped with Constant Force Technology (CFT) anti-backlash lead screws and nuts, providing the additional traction control and precision required for high quality 3D printing.

Driving the UG Series actuators are StepSERVO™ motors from Applied Motion Products®. These motors are available on all PBC Linear mechatronics enabled systems. They offer faster print times and increased accuracy due to greater torque, as well as decreased energy usage. The WorkSeries family of large format printers from 3DP exemplify the convergence of optimized electronic design and optimized mechanical design. Utilizing SIMO technology as the mechanical backbone, 3DP has created a large format 3D printer with a huge useable print area that maxes out at 1 m x 1 m x 0.7 m.

Linear motion and mechatronic solutions from PBC Linear have been featured in large format 3D printers at trade shows and in articles. In the recent past, PBC Linear® has received widespread attention via the International Consumer Electronics Show and ATX West. The industrial strength SIMO Series actuators have profoundly shown their ability to enable precision-grade 3D printing over the large build area of 1 meter x 1 meter x 0.75 meter. PBC Linear has demonstrated this in conjunction with 3D Platform and its WorkSeries industrial strength 3D printers.

In a Design World article entitled 5 Considerations for Scanning, Printing, and Subtractive Machining Design. In this article, the focus is on five areas of evaluation regarding additive and subtractive equipment. These areas affect the quality, repeatability, and life of a given system, and they include:

In addition, the article goes on to discuss an example of mechatronics enabled application using the experience with Trinity Labs, a cartesian robotics research and development company.