In special cases, an assembly or maintenance technician may need to shorten the length, add a groove, machine a flat, or in some other way modify a linear bearing. One disadvantage of a linear ball bearing is that a user cannot remove the end cap, balls, raceways, etc. and modify the bearing in any way. Simplicity plain bearings however, can be machined to accommodate special assembly needs. The outer shell of the standard bearings is aluminum and easily machined using standard tooling. Some non-standard bearing shells may be made of steel or stainless steel and the appropriate standard tooling should be used. The machining instructions below are applicable to FL, FM, FJ, PS, and PSF series of bearings.

If a large quantity of special parts is required, a custom bearing solution may be more cost effective. If you need to modify more than just a few bearings, be sure to ask an Application Engineer about other options.

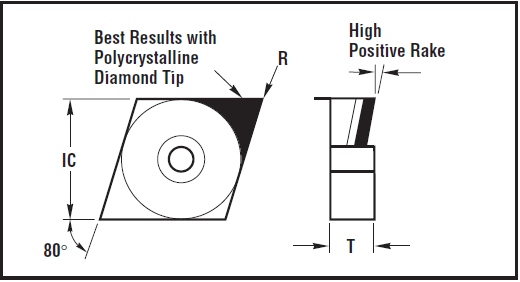

It is best to use high positive rake polycrystalline diamond tip inserts. Carbide cutting tools will only work with an extremely high positive rake. These are necessary so as not to cause damage to the relatively soft composite bearing liner material on the I.D.

Also, be aware that if bearings are machined or modified in any way, the PBC Linear warranty becomes null and void.

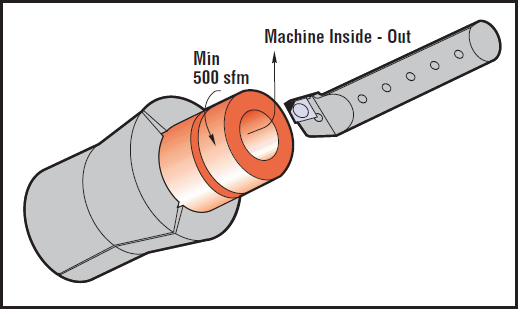

If you are attempting to machine the inside diameter of the bearing to increase running clearance, first be sure that this is necessary. Often adjustments to the alignment of the shafting will eliminate any problems associated with running clearance. If machining the I.D., be sure that more running clearance is actually needed! This is NOT a solution for binding

To solve binding problems, first check:

NOTE: The liner that is removed is also potential wear life that is removed!

When using insertable tools, polycrystalline diamond tip inserts with a high positive rake are best.

Carbide tools will only work with an extremely high positive rake. Tolerance and finish will be more difficult to hold.

CAUTION: The bearing liner is relatively thin on each side of the bearing wall. At the time of manufacture, tight tolerances on size, roundness, and concentricity are maintained. Any after sale modifications may compromise this quality. PBC Linear will not be held responsible for any damaged or destroyed product that is machined or altered.

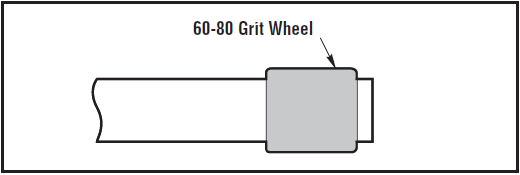

To hone or ID grind the liner, a 60-80 grit grinding wheel is recommended.