In today’s world of space-conscious technology like flat-screen TVs, thin laptops and smart phones, the demand for space-saving printed circuit boards and system-on-a-chip (SOC) is on the rise. Assembling printed circuit boards requires repeatable performance, and extremely subtle precision that is often too expensive for educational and small business markets. At Brown University, Professor Harvey Silverman’s team devised a multi-axis circuit board assembly system to automate the process while staying within a suitable cost.

To accomplish the task of circuit board assembly, Professor Silverman needed a linear motion solution that could position tiny surface mount devices (SMD’s) such as capacitors and resistors of 0402 size (0.040 x 0.0240 inch), and accurately place them onto solder paste to adhere to the board. These tiny parts needed to be handled delicately, with the ability to adjust mid-operation to correct for misalignment. Finally, Professor Silverman needed to find a way to ensure all parts were in the right place.

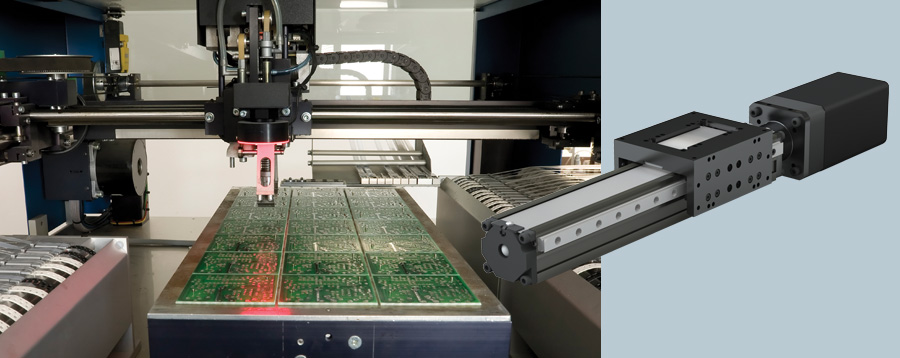

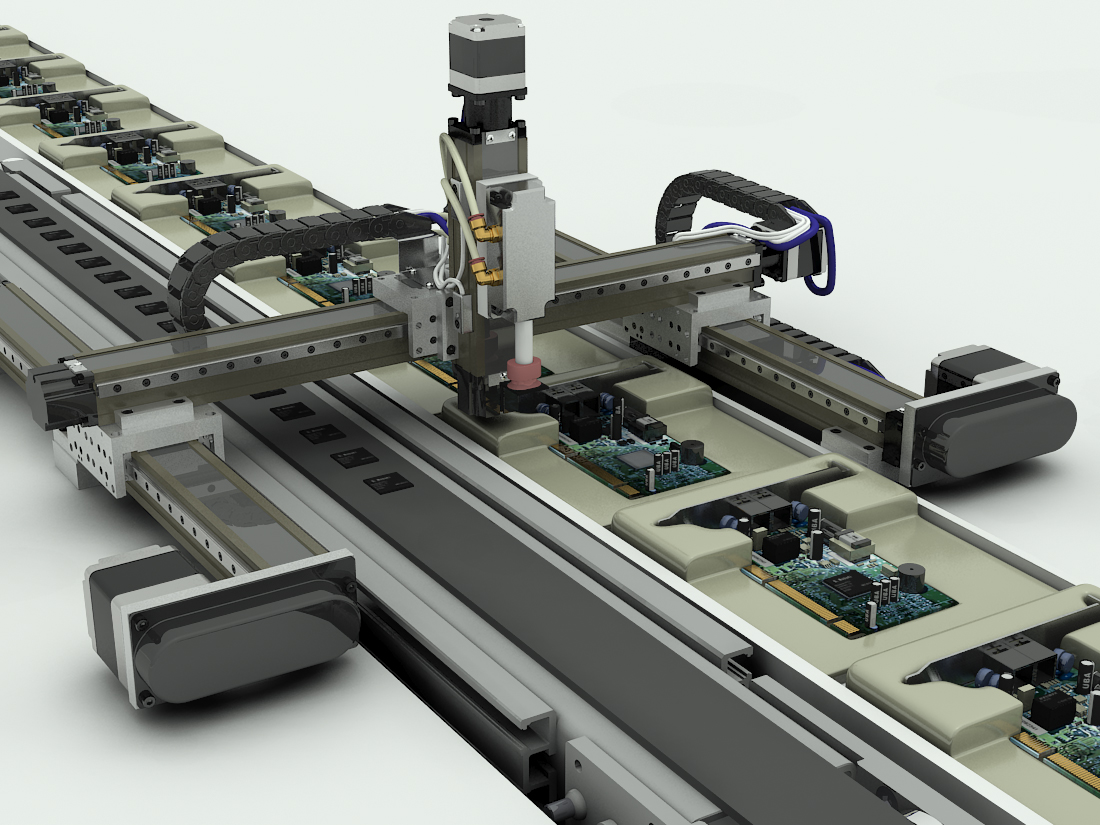

Over the course of a year, Professor Silverman incorporated product assistance from PBC Linear application engineers to come up with a working solution. Three ML series lead screw driven mini-actuators were assembled in a 12 x 14 inch XYZ system, and then used to automate the surface mount assembly process. More specifically, two of the ML actuators would accurately determine the XY position while the third moved a vacuum needle, or part-grabber, up and down.

The ML series, mini-actuator XYZ gantry was controlled with a vision system. The compact, 28 x 32 mm profile of the mini-actuator offered the optimal size for small-scale circuit board assembly. In addition, the ML series is equipped with state-of-the-art components for accurate linear positioning. They include a ‘dove-tail’ style carriage comprising 14 plain bearing surfaces for high rigidity and smooth travel, single or dual external linear guide supports for enhanced stability, and a full line of accessories for use in multi-axis systems.

The diameter of our lead screws is one of the largest available in the industry for actuators of this size, which help to overcome the detriments of the phenomenon known as ‘critical speed’. They are also Teflon coated to increase life while lowering friction and drag on the motor.

A server was also added to allow rotation of the part. In addition, the gripper assembly was outfitted with a small camera to locate loose parts and give feedback to the user utilizing software designed by Professor Silverman. The camera compares images of assembled circuit boards to identify where all the pieces need to go and signals the gripper to re-align if adjustment is necessary. The system can also be switched over to manual control for special assembly projects.

Overall, Professor Silverman was very pleased with the low cost solution from PBC Linear, as well as the ML actuator's ability to perform the required tasks at hand.