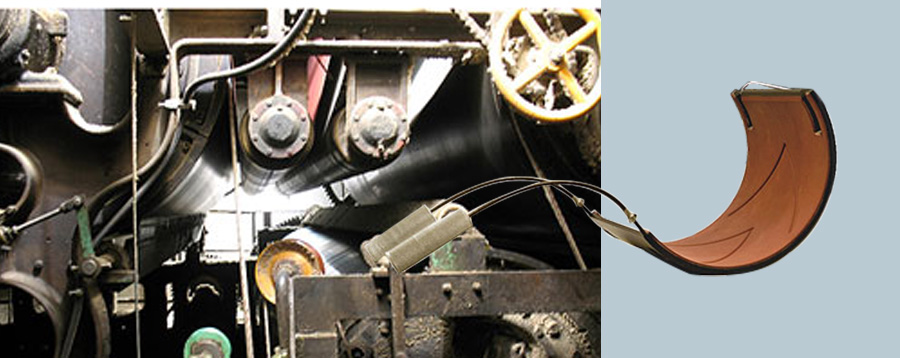

PBC Linear implemented a custom made sensor bearing into large paper plant dryers for a paper plant.

Previously using Babbitt bearings, the paper plant was experiencing constant downtime, using an immense amount of energy, and reporting loss of product, and profits. The original Babbitt bearings installed into the paper dryers were only functioning for a short period of time before they needed to be changed out and replaced. This is mostly due to the immense force required to start-up the paper drying process. In the beginning start up stages, the cast iron dryers are running against the Babbitt bearings which are typically comprised of bronze, tin, or lead. This extremely pressurized metal to metal contact creates a large amount of friction and results in incredible wear on the Babbitt bearings—dramatically reducing their product life.

With the introduction of the new PBC Linear sensor bearings into the cast iron dryer system, the self-lubricating technology greatly reduced the amount of energy needed for the machine’s start up by 90%! This not only created less wear and tear on the bearings and dryers but also significantly lowered energy costs.

The decreased wear and tear on the bearings also contributed to extended product life—allowing the machines to run even longer without undergoing start-up. The bearings sensors also signal technicians at when preventative maintenance is required, which further allows the condition of the bearings to be kept in running condition.

Originally, three custom made PBC Linear sensor bearings were used as a trial operation in the mill out of 72 possible replacements. The clear improvements of the sensor bearings over the Babbitt bearings caused nine additional sensor bearings to replace the old system, energy-wasting bearings.