With each new technological advancement, there is often an evolution of machines to do more with less space, and subsequently the need for smaller components to make up those machines. This is evident in medical diagnostics and laboratory science, as well as robotics and automation industries where small frame sizes combined with higher speeds, torque, and accuracy are increasingly requested.

PBC Linear is continuing to expand its linear actuator product line to meet this rising demand. In addition to our existing lineup of small, medium, and large mechatronics products, we are introducing a more extensive group of compact linear actuator solutions to provide engineers with more flexibility in their designs and budgets.

A linear actuator is a machine that takes the rotational motion of a motor and translates that energy into linear movement. Actuators can be categorized by their drive mechanisms, such as hydraulic, pneumatic, and electromechanical. Electromechanical is the most common drive-type of linear actuator. Examples of drives include rack & pinion, belt, ball screw, or lead screw. Belt and rack & pinion drives are typically used in heavy or long travel applications, while screw drives utilize their pitch and lead to help determine speed and precision in shorter applications.

The product summaries below represent the newest additions to our compact actuator product line. These electromechanical actuators are comprised of either a ball screw or lead screw, along with a wide variety of motor and screw configurations that offer their own unique solutions.

The L Series linear actuators combine lead screws, nuts, and hybrid stepper motors into three different configurations: Captive, Non-Captive, and External Nut. Each of these types provides high precision and exceptional efficiency within compact applications. Additional advantages include:

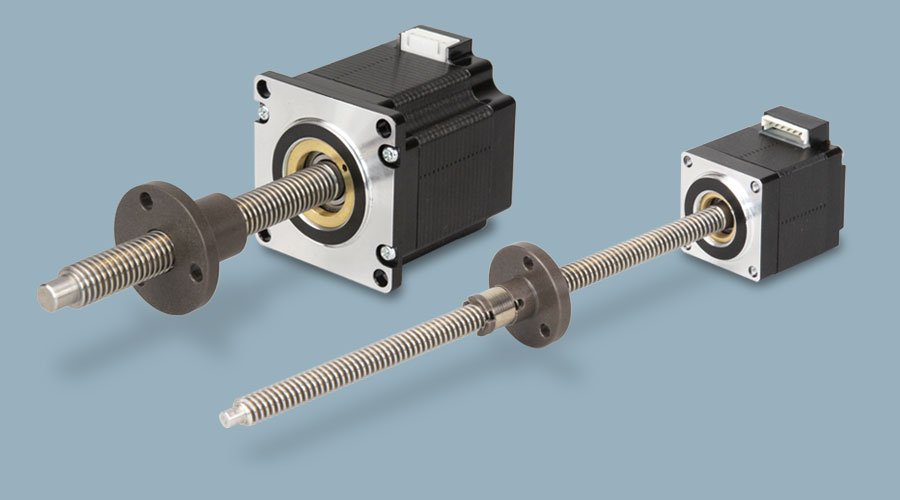

The LE Series Stepper Actuators combine lead screws and the popular external nut design with motors that are typically fixed in position. In this configuration, the shaft of the stepper motor is replaced with a lead screw that, when rotated, drives the nut along the length of the screw. This design is useful for a wide range of applications, but can be susceptible to flex and vibration issues with longer length lead screw designs. Main features include:

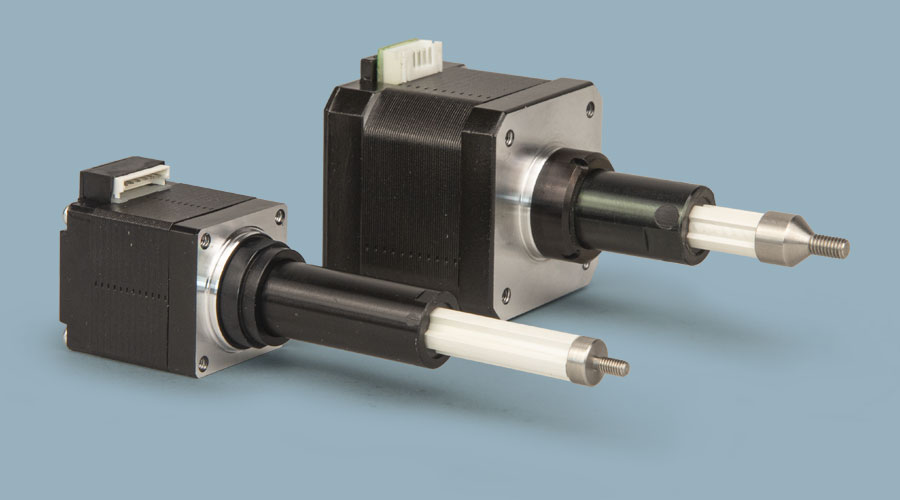

The new LC Series Actuators use a captive type of stepper motor that is integrated with a lead screw and nut. In this design, a screw is attached to a splined shaft that is driven in and out of the motor. The length of the splined shaft is dependent on the length of the motor, allowing for a travel distance of usually only a few inches. LC Actuators are ideal for plungers or pushers in sorting or assembly operations, and is a good choice for applications that lack a mechanism to prevent the lead screw or nut from rotating. Other advantages include:

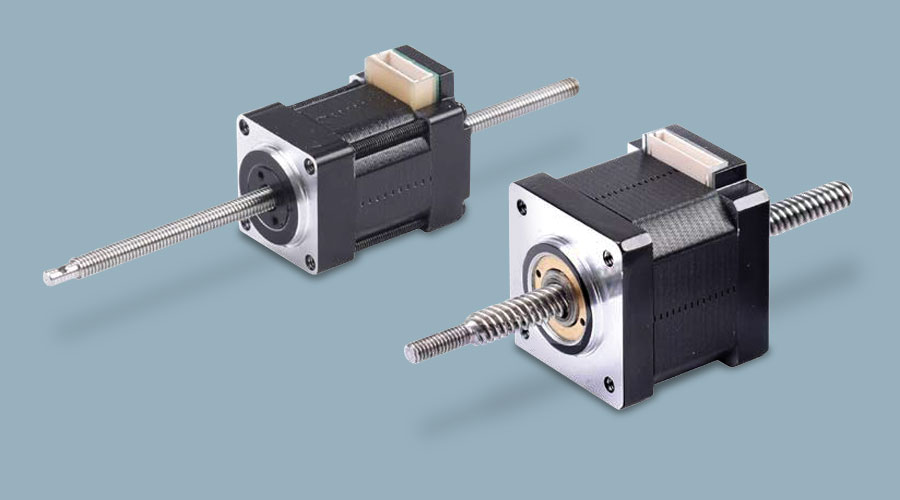

The new LN Series Actuators feature a non-captive type of stepper motor combined with a lead screw and nut. In a non-captive design, the nut is incorporated into the motor’s rotor. As the rotor spins, it can either pass the leadscrew through the shaft, or move the motor along the length of the lead screw where the screw is in a fixed position. When both ends of the lead screw are supported, the maximum length of the lead screw can be greater than that of an actuator with external nut, making it a popular option for longer travel. Additional design advantages include:

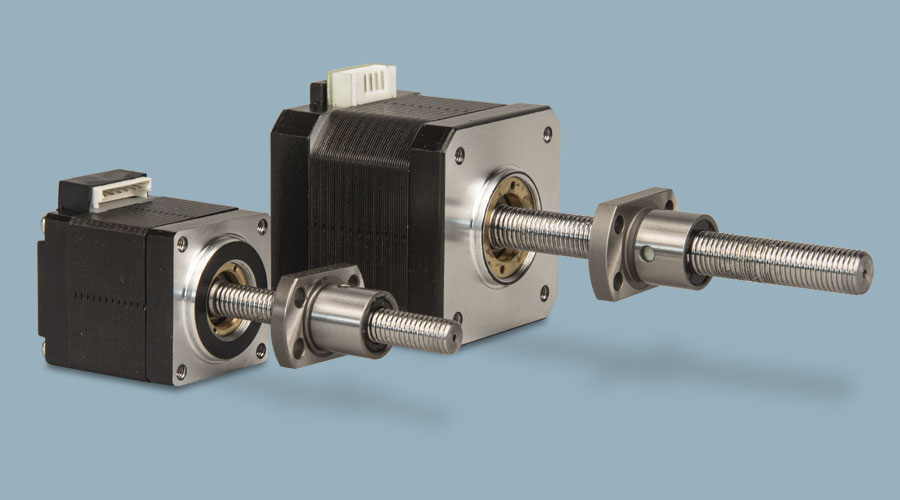

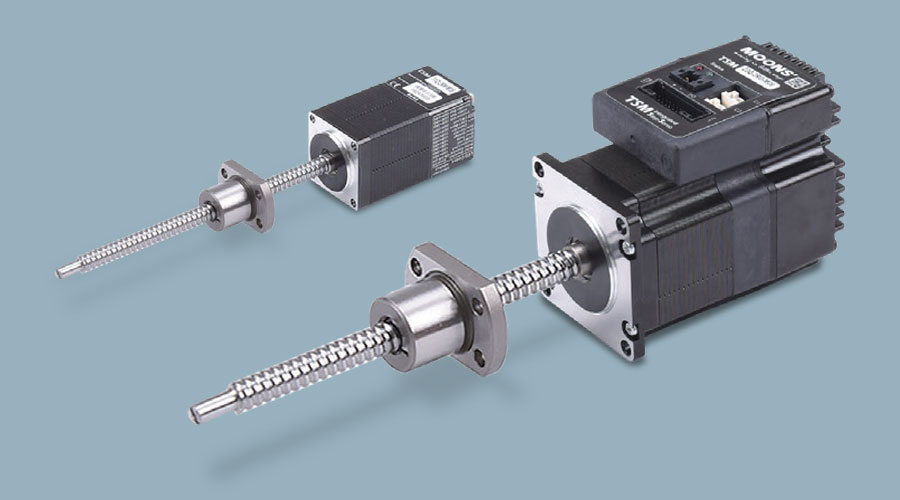

Our new BE Series Actuators feature a ball screw and external nut integrated with a stepper motor. As the motor rotates, the ball nut moves linearly along the screw. These are similar to a lead screws, but offer higher operating frequency and efficiency where recommended. Additional design advantages include:

The new TSM Series Actuators incorporate integrated drivers, encoders, controllers and stepper motors into our ball screw system to provide customers with an all-in-one solution. The closed-loop, step-servo mode provides precise positioning and velocity control for harsh applications and can accommodate a wide range of inertial and frictional load changes. Additional features include:

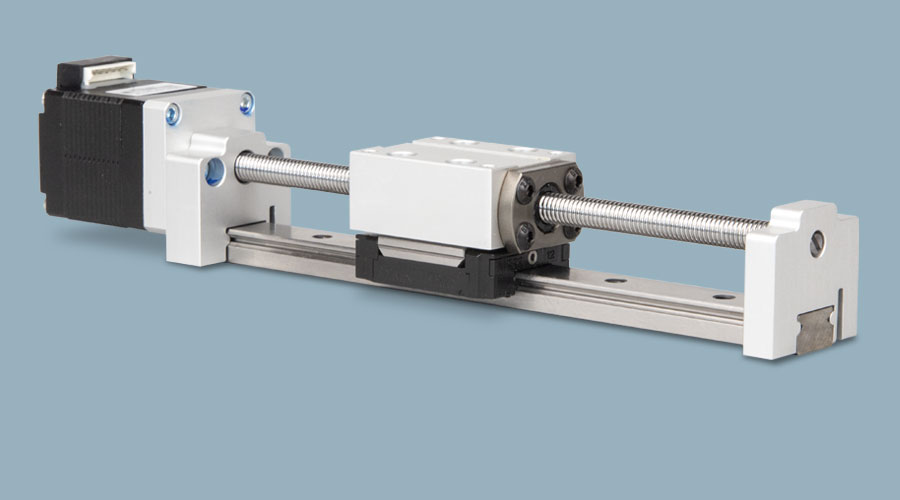

The new MS Series Linear Slide Actuators utilize a lead screw and standard polymer nut to drive payloads along a 12 or 15 mm profile rail linear guide for higher precision and strength. These cost-effective actuators are compact, easy to assemble, and provide quiet operation. Additional features include:

Our new MLA Series Miniature Linear Actuators offer a variety of lead screw and ball screw options that can be easily integrated into small-space applications. This helps customers quickly bring new products to market, while reducing labor costs. MLA Actuators are optimal for industries such as medical science, factory automation, biomechanical analysis, and semiconductor fabrication. Additional design advantages include:

For more technical information on lead screws and linear actuators from PBC Linear, please enjoy any of this related content: